![]()

A Breakthrough in Metal 3D Printing

From Markforged, the company that revolutionized 3D printing with composite carbon fiber, comes

a leap in additive metal manufacturing. The Metal X greatly accelerates innovation,

delivering metal parts overnight using a new technology at a fraction of the cost. Leave

20th century manufacturing in the dust and create anything from industrial replacement

parts to injection molds to working prototypes.

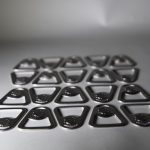

ADAM – Atomic diffusion additive manufacturing

The intersection of 3D printing and metal injection molding, ADAM is an all new

way to build metal parts.

DESIGN – CAD your part, upload the STL, and select from a wide range of metals. Eiger

software does the rest making printing the right part easy.

GREEN PART – Just like metal injection molding, as-printed parts are “green” and scaled

up to account for shrinkage during sintering. In this state the part can be easily polished by hand.

SINTER – Green Parts go through a washing stage to remove some of the binder. They are then

sintered in a furnace and the metal powder fuses into solid metal.

FINAL PART – Pure metal and up to 99.7% dense, the final parts are ready for use. They can be

processed and treated just like any other metal parts.

| PRINTING | |

| Printing Technology: | Fused Filament Fabrication |

| Material Compatibility: | Stainless Steel 17-4, 316L Aluminum 6061,7075 (beta) Inconel IN Alloy 625 (beta) Tool Steel A-2, D-2 (beta) Titanium Ti-6Al-4V (beta) |

| Build Size(xyz): | 9.84 x 8.66 x 7.87 Inches (250 x 220 x 200mm) |

| Extruder: | Quick Change |

| Accuracy: | 50 Micron (.002″ xy) 100 Micron (.004″ z) |

| Layer Resolution: | 50 Micron |

| Laser Scanning Res | 50 Micron |

| Laser Accuracy | 1 Micron |

| MECHANICAL | |

| Printer Dim (L x W x H): | 22.6 x 18.4 x 56.37 Inches (575 x 467 x 1432 mm) |

| Chassis: | Anodized Aluminum Unibody |

| Build Platform: | Kinematically Coupled |

| Draft Blocking Enclosure: | Yes |

| Printer Weight: | |

| Printer Shipping Weight/Dim: | |

| SOFTWARE | |

| Software: | Cloud Enabled |

| Supported OS: | Mac OS 10.7 Lion +, Win 7+, Linux* |

| Supported Browser: | Chrome 30+ |

| Supported Files: | .STL |

| Connectivity: | WiFi, Ethernet, USB Drive |

17-4 STAINLESS STEEL

17-4 stainless steel combines high strength, corrosion resistance, and hardness, making it widely used in aerospace, medical and petroleum industries. We use it for assembly fixtures and tooling on the Mark X.

316L STAINLESS STEEL (Beta)

Also know as marine grade stainless steel, 316L stainless steel exhibits very good corrosion resistance and excellent weldability.

A2 TOOL STEEL (Beta)

A-2 tool steel is air-hardened with excellent impact resistance. We use it for punches, dies, and form tooling on the Mark X.

D-2 TOOL STEEL (Beta)

The high carbon and chromium content of D-2 tool steel provides great hardness and abrasion resistance (but not as tough as A-2). D-2 is often used for cutting tools.

TITANIUM Ti-6Al-4v (Beta)

Ti-6Al-4V, also known as Grade 5 titanium, is ideal for lightweight applications requiring high tensile strength and corrosion resistance. It is widely used in aerospace applications such as airframe components and turbine blades.

6061 ALUMINUM (R&D)

As a general purpose aluminum, 6061 combines good machinability, strength, and weldability. It can additionally be anodized for a good surface finish. We use it for many of the machined components in our industrial series printers.

7075 ALUMINUM (R&D)

7075 aluminum is one of the strongest aluminum alloys available. With a high strength-to-weight ratio, 7075 is stronger than many common structural steels.

H13 TOOL STEEL (Beta)

H13 is a hot work steel widely used in die casting and tooling applications. Alloyed with chromium, molybdenum, and vanadium, it is known for its strength and resistance to thermal shock.

INCONEL 625 (Beta)

Inconel’s strength combined with its impressive heat resistance makes it ideal for heat and pressure shielding. This superalloy is used in jet engines and medical applications, and is very hard to machine.

COPPER (Beta)

Known for its high thermal and electrical conductivity, ductility, and machinability, copper is widely used in heat exchangers, as well as electrical and construction applications.