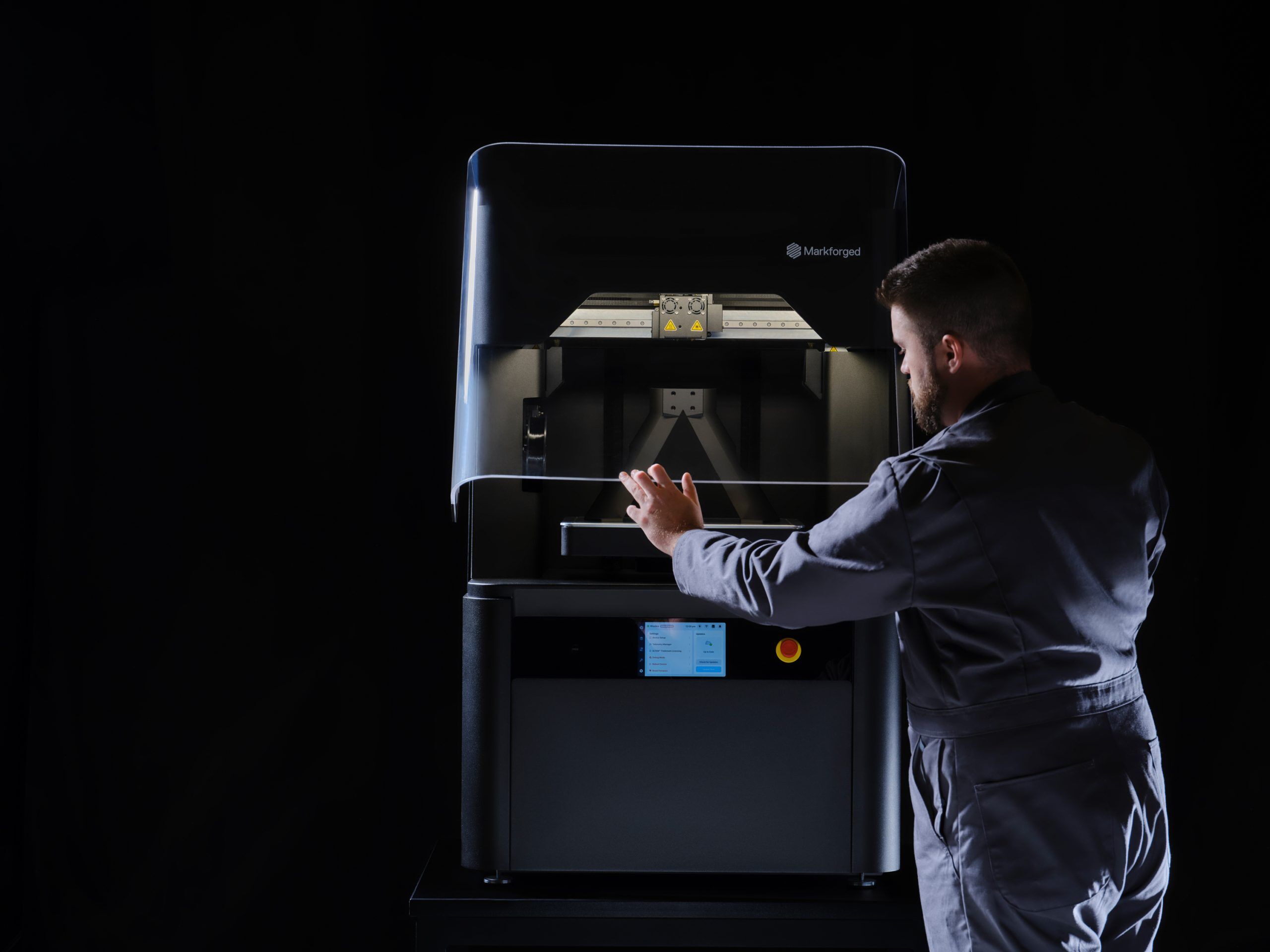

Markforged FX10 3D Printer – Introducing the most versatile tool for your factory floor.

FX10 Features

FX10 Features

• Designed for the Factory Floor

• Auto Bed Leveling (no shims)

• 2X Faster/Larger Build Volume vs. MF X7

• Extended Life Plastic Nozzle (After 125 800cc Onyx Spools)

• Extended Life Fiber Nozzle (After 66 150cc CF Spools)

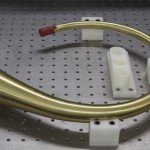

• Extended Life Tubing (Lasts 3X Longer than MF X7)

• Print 3,200cc Onyx unattended vs. 800cc MF X7

• Reusable multi-use print-sheet

• Heated Build Chamber/Print Bed (up to 60C)

• Build Volume 14.8″ x 11.8″ x 11.8″ (xyz)

• Load up to 4 800cc Filament spools with auto changeover

• Vision Part Inspection Camera – Inspect every layer unattended.

• Simulation and Inspection Software

• Printbed Overview Camera – Takes part picture every 5 part layers

![]()

About the FX10

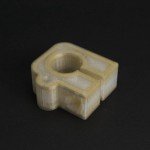

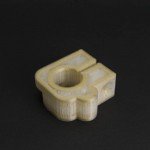

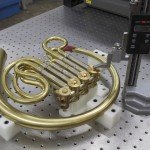

Markforged FX10 3D Printer is the next generation industrial composite 3D printer — the result of years of engineering innovation and technological advancement. Built on the success of the Markforged X7, its sole purpose is to deliver strong, accurate parts every print. FX10 features a new modular architecture that’s designed for upgradability and print head-mounted optical sensors that can verify dimensional accuracy of parts and assess device health and performance. It utilizes automatic calibration and material changeover, yielding a simple, low-touch user experience that mitigates the need for dedicated operators. Markforged software controls every aspect of FX10 — so users can quickly go from CAD to print, share parts across their organization, and monitor fleet performance from a central location. FX10 is the versatile tool that supercharges your manufacturing productivity and profitability.

| PRINTING | |

| Printing Technology: | Fused Filament Fabrication (FFF)Composite Filament Fabrication (CFF) |

| Material Compatibility: | Carbon Fiber, Onyx |

| Build Vol(xyz): | 14.8 x 11.8 x 11.8 Inches (375 x 300 x 300mm) |

| Extruders: | Dual Quick Change |

| Accuracy: | (.005 – .0100″ xyz) |

| Layer Resolution: | 125 – 250um |

| Min Feature Size (Nylon Only): | 1.6mm |

| Min Detail Size: | 0.8mm |

| Min Wall Thickness (To Add Fiber) : | 2.6 – 3.0mm |

| Moving or Interlocking Parts (Clearance between parts): | 0.5mm |

| Overhangs & Supports: | 40+ Degrees Requires Support |

| Nozzle Widths: | Plastic/Nylon = .4mm wide / Fiber = .9mm wide |

| Filament Diameter: | Carbon Fiber = .38mm Plastic & Nylon =1.75mm |

| MECHANICAL | |

| Printer Dim (L x W x H): | 30 x 25 x 48 Inches (760 x 640 x 1200 mm) |

| Chassis: | Anodized Aluminum Unibody |

| Build Platform: | Precision Machined Aluminum |

| Draft Blocking Enclosure: | Yes |

| Printer Weight: | 240lbs |

| Printer Shipping Weight | 300lbs |

| SOFTWARE | |

| Software: | Cloud Enabled |

| Supported OS: | Mac OS 10.7 Lion +, Win 7+, Linux* |

| Supported Browser: | Chrome 30+ |

| Supported Files: | .STL |

| Connectivity: | WiFi, Ethernet, USB Drive |

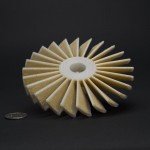

Onyx

Onyx

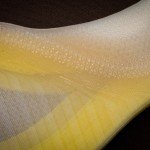

Our Most Advanced Material For High-Performance 3D Printing. Onyx is a Black Nylon

infused with Chopped Carbon Fiber.

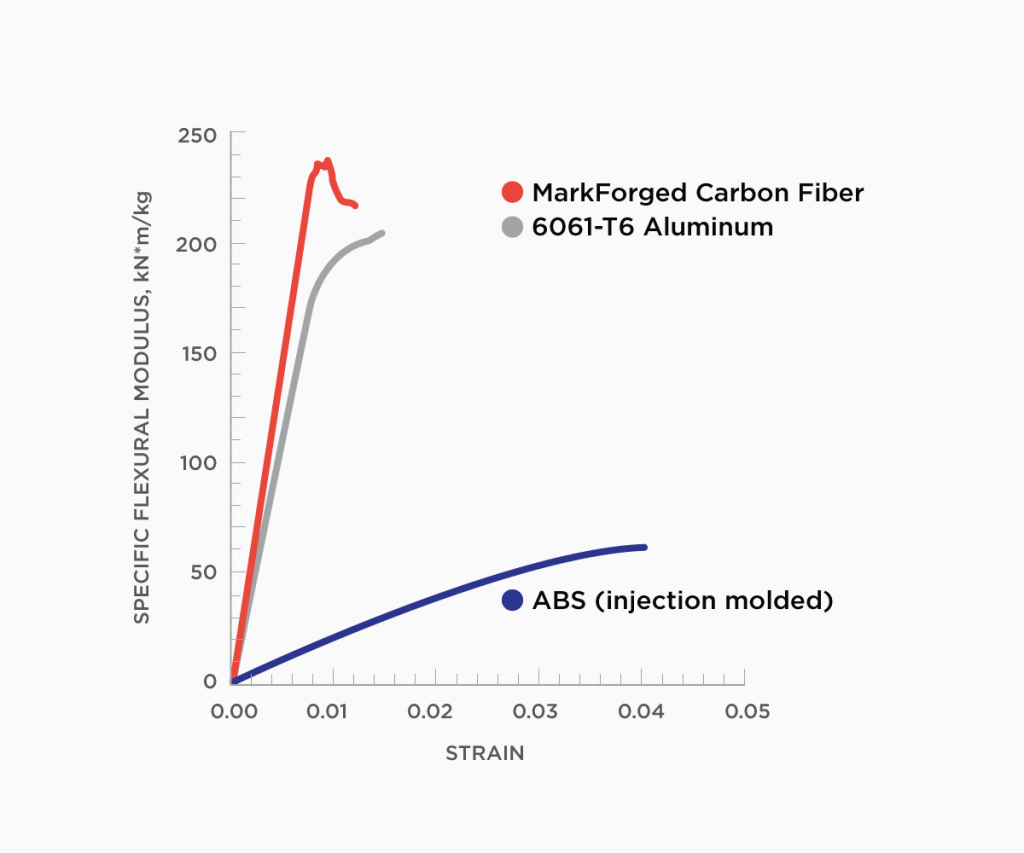

ONYX is vs. ABS

233% Tougher

39% Stronger

47% More Heat Resistant

27% Stiffer

ONYX – NO POST PROCESSING Delivers stunning matte black finish without mechanical or chemical finishing.

ONYX – ACCURATE STABLE PARTS Added Micro-Carbon Fiber delivers increased dimensional stability and near 100% print success rate.

ONYX – MARKFORGED ADVANTAGE Onyx can be used alone or further reinforced with Fiberglass, Kevlar & Carbon Fiber.

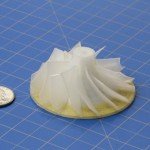

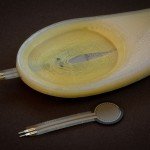

Carbon Fiber

Carbon fiber has the highest strength to weight as well as the highest thermal conductivity. Perfect for applications requiring the greatest possible stiffness and strength.

Higher strength-to-weight than 6061 Aluminum

The Mark Two prints outer contours and curves in engineering nylon and fills each part with close-packed reinforcement in continuous carbon fiber, Kevlar or fiberglass.

The printer actively switches between two nozzles during a print, creating fiber-reinforced plastic parts with a strength-to-weight ratio better than aluminum.